Hardware Development

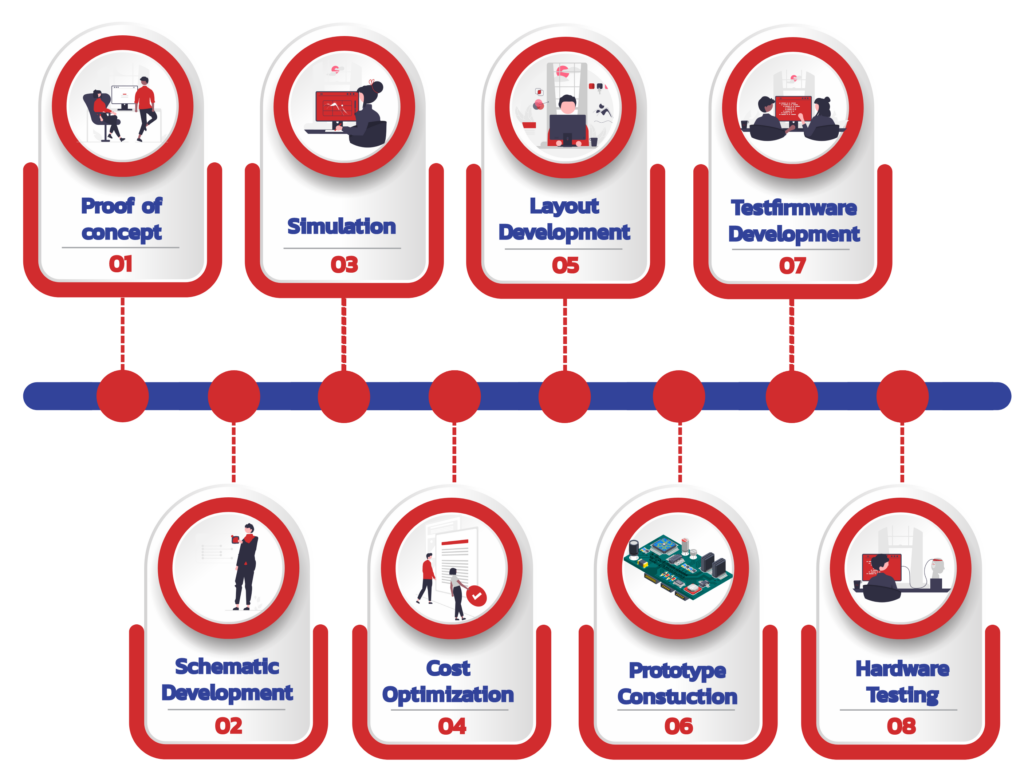

HW Development Cycle

Fusion Sensorik & Messtechnik GmbH ensures, reliable product development, through years of experience and extensive expertise in all relevant areas of hardware development technology.

Our Offer Includes:

- Analog and digital circuit design

- Microcontroller technology and sensor technology

- Power electronics and high-frequency technology

- Development of energy-efficient and battery-operated circuits

Our development processes are designed to identify potential challenges early on and address them proactively, making the development process both efficient and cost-effective.